Choose the Right Agricultural Drone, Click Here to know

Given the demand for precision agriculture and digital crop production, agricultural drones have become an important part of the modern agricultural industry. Spray application, labor cost efficiencies, complex terain navigation, and rapid health surveillance of crops are just a few of the many benefits provided through the use of drones. However, the selection of a drone for agricultural use should be based on numerous parameters. The selection of the most appropriate drone based on the parameters that impact the operational and financial efficiencies of agricultural productivity is of the utmost importance.

The selection of a drone for agricultural use is not simply a matter of cost. Other important criteria need to be considered including operational requirements, land area, and operational efficiencies.

Define Your Agricultural Operation Needs

Before we begin the selection process, we need to calculate the parameters of the agricultural drones you need based on the five criteria of the mission type, area/periodic frequency, time of operation in one go, accuracy, and the capacity of the load. If we do not specify these five factors, we can easily make an imitation of parameters and purchase an ill fit model for the scenario.

Plant Protection Spraying

The goal of agriculture spraying is to get “uniform coverage, ideal dosage and little to no pesticide drift.” Some crops and situations include rice and corn, wheat, specialty vegetables, and orchards. Drones deliver, low-altitude, accurate, and repeatable spraying unlike traditional airplane or backpack sprayers.

Key Quantitative Parameters:

| Parameter | Explanation | Typical Values / Decision Guide |

| Spray Volume per Acre (or L/ha) | Indicates the amount of liquid required to achieve effective pesticide or nutrient application. Must be aligned with chemical label instructions and crop requirements. | General field practice: 20–30 L/ha (approx. 2–3 L/mu). Low-volume applications: 8–16 L/ha. |

| Tank Capacity / Payload | Determines how much liquid a drone can carry per trip. Directly affects area covered per sortie. | Small drones: 10–20 L. Medium/large & heavy-lift platforms: 30–70 L or up to 50 kg payload. Example: A 40 L tank at 20 L/ha covers ~2 ha per flight. |

| Spray Width & Flight Speed | Defines operational efficiency. Effective coverage per hour = spray width × flight speed. Influenced by wind, droplet drift, fill-up time, and spraying uniformity. | Common spray width: 3–8 m. Operated flight speed typically 3–7 m/s depending on crop and nozzle type. |

| Endurance & Power Supply Strategy | Determines how long the drone can maintain operations under load. Essential for large or distributed farmlands. | Electric drones: 20–40 min (heavily affected by payload). Heavy-lift or hybrid power: 1–3 hours+. For large farms: choose high-payload / long-endurance or quick-swap battery systems. |

Spray Accuracy & Technical Considerations:

| Technical Factor | Importance | Professional Notes |

| Airflow Downwash / Air-Assisted Spraying | Ensures droplets penetrate crop canopies, especially in orchards or tall crops. | Enhances deposition, reduces drift, improves uniformity in 3D crop structures. |

| RTK Positioning + Automated Flight Paths | Ensures consistent spraying lines and repeatable coverage across multiple operations. | RTK accuracy improves track overlap control, minimizes missed or overlapped areas. |

| Nozzle Droplet Spectrum (VMD) | Affects droplet size, drift risk, and application efficacy. | Must match crop, chemical label, and wind conditions. Droplet size changes with flight speed and flow rate, requiring field calibration. |

Selection Recommendations:

| Farm Scenario | Recommended Drone Type | Key Reasons |

| Small Plots, Orchards, Uneven Terrain | Multirotor, 10–20 L class | High maneuverability, obstacle avoidance, terrain-following radar ideal for irregular fields. |

| Medium to Large Fields (tens–hundreds of acres) | Mid-payload 30–50 L or 10–25 kg class, supported by battery-swap stations | Balances efficiency and cost; suitable for continuous daily spraying. Recommended for regular pesticide and nutrient application cycles. |

| Large-scale, High-Frequency, or Continuous Operations | Heavy-lift / hybrid-power drones or VTOL fixed-wing hybrids | Long endurance reduces downtime; ideal for plantations or commercial service providers needing multi-hour daily operation. |

During use, it is necessary to strictly adhere to the dosage on the pesticide label and local aerial spraying/spraying regulations; and to maintain environmental and personnel safety by adopting BMP (Best Practices).

Crop Monitoring and Mapping

The purpose of the mission is drone crop monitoring for the estimation of NDVI/NDRE and other crop health indices, together with the generation of maps depicting crop coverage, identification of areas with specific pests and diseases, and determining the levels of soil moisture from remote sensing data (RGB, multispectral, thermal infrared, LiDAR) to support zone-specific management (variable application of fertilizers, prevention and control, targeting).

Key Quantitative Parameters:

| Parameter | Detailed Explanation | Typical Industry Values / Calculation |

| Spray Volume per Acre (or L/ha) | The liquid application rate required to achieve effective pesticide or nutrient coverage. The required dosage varies by crop type and chemical formulation. Always follow the crop-specific and label-specific recommendations. | General field recommendation for herbicide, foliar fertilizer, and nutrition spraying: 20–30 L/ha (≈ 2–3 L/mu). Low-volume scenarios: 8–16 L/ha. |

| Tank Capacity / Payload | Determines how much liquid the drone carries per sortie. Directly affects operational efficiency and area covered per mission. Area per tank = Tank Volume (L) ÷ Spray Volume (L/ha). | Small spraying UAVs: 10–20 L. Medium/large or heavy-lift UAVs: 30–70 L or up to 50 kg payload. Example: A 40 L tank at 20 L/ha covers ≈ 2 ha per flight. |

| Spray Width & Flight Speed | Spray width (m) combined with flight speed (m/s) determines hourly field capacity. Real output may be affected by crosswind, droplet drift, refill time, and spraying efficiency. | Typical spray width: 3–8 m. Common flight speed: 3–7 m/s, depending on crop height and nozzle configuration. |

| Endurance & Battery Change / Refueling Capability | Defines how long the UAV can operate under load. Critical for large or dispersed farmlands. Load significantly affects endurance for electric UAVs. | Electric UAVs: 20–40 minutes under load. Hybrid or heavy-lift platforms: 1–3+ hours. For long-distance or large-scale fields, choose high-endurance, high-payload, or quick-swap battery systems. |

Spray Accuracy & Technical Considerations:

| Technical Factor | Why It Matters | Professional Details |

| Airflow Downwash / Air-Assisted Spraying | Improves canopy penetration and ensures droplets reach the lower leaf layers. Essential for orchards and 3D structured crops. | Enhances deposition uniformity, reduces drift, and increases efficacy on dense or tall crops. |

| RTK High-Precision Positioning & Automated Flight Paths | Ensures consistent flight lines, accurate repetition, and minimal overlap or gaps. | RTK centimeter-level accuracy improves track alignment and chemical use efficiency. |

| Nozzle Droplet Spectrum (VMD) | Determines droplet size distribution, affecting drift, adhesion, and chemical effectiveness. | Must match chemical label requirements. Research shows flight speed and spray rate alter droplet size, requiring on-field calibration for optimal performance. |

Selection Recommendations:

| Farm Type / Scenario | Recommended Drone Category | Rationale |

| Small Fields, Orchards, Uneven Terrain | Multirotor UAVs, 10–20 L class, equipped with obstacle avoidance & terrain-following radar | High maneuverability, precise altitude control, ideal for tree crops and irregular field shapes. |

| Medium to Large Fields (tens to hundreds of acres) | 30–50 L medium-payload UAVs or 10–25 kg payload platforms, supported by battery-swap stations | Balanced efficiency and operational cost. Effective for scheduled pest control cycles. Optimized for daily service providers. |

| Large-Scale or Continuous Operation | Heavy-lift UAVs, hybrid-power systems, or VTOL fixed-wing hybrids | Extended endurance minimizes downtime from frequent refills and battery changes. Suitable for plantation-scale or professional outsourcing operations. |

If you need to do high-frequency agricultural monitoring, you need to get a multi-rotor agricultural drone you can deploy quickly and has average battery life and can use multispectral cameras. If you need to do high precision mapping, like a topographic survey or 3D modeling, then it’s better to use a fixed-wing drone or a vertical take off and landing (VTOL) drone that can stay in the air for a long time and has LiDAR or high resolution multispectral sensors to ensure the mapping data will be accurate.

Sowing Seeds and Fertilizing

Dispersing tasks often involve spreading seeds, granular fertilizers, or biocontrol agents with the intention of attaining even coverage or specific application as required. At the moment, spreading is different from liquid spraying as it places greater demands on the load-bearing capacity, dispersal mechanisms, and terrain stability.

| Category | Key Factors | Details / What to Consider |

| Critical Quantitative Parameters | Payload Capacity (kg) & Hopper Volume (L) | Determines spreading area per flight. Granular materials are heavier than liquids. Coverage per flight should be calculated based on spreading rate (kg/ha). Heavy-lift drones (30–100 kg class) are more suitable for large-area spreading. |

| Spreading Rate & Uniformity | Directly impacts reseeding and fertilization effectiveness. Uniformity depends on spreading mechanisms (rotary disc, vibrating gate, chute) and flight speed. Field calibration (test spreading) is essential. | |

| Flight Altitude & Wind Tolerance | Spreading is highly sensitive to wind. Higher altitude leads to drift. Recommended low-altitude flights in stable wind conditions. | |

| Power System & Energy Constraints | Impact of Granular Materials on Endurance | Solid materials add significant weight, increasing power consumption and reducing flight time. For multi-hour or large-scale tasks, hybrid-power drones or heavy-lift platforms are recommended to maintain operational efficiency and minimize downtime. |

| Operational Recommendations | Field Test Strip Calibration | Conduct test strips before large-scale spreading to measure uniformity and fine-tune speed, altitude, and discharge rate. |

| Variable-Rate Spreading Based on Field Data | Combine spreading plans with soil or vegetation datasets (e.g., NDVI-based variable fertilization maps) to improve efficiency and crop yield. |

Detailed Explanation of Core Selection Parameters

It can be hard to judge the performance of a drone based on reviews alone. For example, when buying agricultural drones, looking at the following aspects may be useful: default specifications versus the reviews (payload capacity, flight time, and working radius, also, energy system and stability). As for compatibility and expandability, it would be better to compare to the real functioning of the drone. For example, the potential uses (spraying, monitoring, seeding).

Load Capacity

Payload capacity refers to the maximum weight a drone can carry during flight, including pesticides, fertilizers, seeds, or sensor equipment. It directly determines the coverage area, operational efficiency, and applicable scenarios for a single operation.

| Drone Category | Payload (kg) | Typical Use Cases | Example Models / Notes | Selection Recommendation |

| Entry-Level Multirotor | 5–15 kg | Small-area spraying, high-frequency monitoring (orchards, greenhouses, small farms) | — | For small plots or precision monitoring, prioritize low-payload, highly maneuverable multirotors. |

| Medium to Heavy-Lift Drones | Up to 50 kg+ | Large-area spraying, material transport, seed or fertilizer spreading | VastArrive Electric Drone Series | For medium to large farms, prioritize mid-to-heavy payload drones with high operational efficiency. |

| Ultra-Heavy-Lift Drones | Up to 100 kg | Intensive, large-scale operations | VastArrive VA-W280 | For large-scale or continuous operations, choose ultra-heavy-lift drones to maximize coverage per flight and reduce downtime. |

Flight Time and Operational Radius

Flight time and operating radius determine the coverage area, operational efficiency, and whether frequent return flights for resupply are required for each agricultural drone mission.

| Drone Category | Endurance | Typical Use Cases | Example Models / Notes | Selection Recommendation |

| Electric Multirotor | 30–60 min | Small-area spraying, short-cycle or dispersed monitoring tasks | — | For small plots or temporary monitoring, choose mid-endurance drones to balance cost and operational needs. |

| Fixed-Wing / Hybrid-Power Drones | 1 hour+ up to several hours | Large-area spraying, remote fields, long-distance monitoring | -VastArrive Electric VTOL Fixed-Wing -VastArrive VA-W280 Heavy-Lift | For large or dispersed fields, prioritize high-endurance drones to minimize frequent return-to-base operations and maximize efficiency. |

Power System and Flight Stability

How effective, safe, and easy to repair the system is depends on the type of the agricultural drone’s power system. For example, battery-powered drones are perfect for light to medium payloads because of easy maintenance and low noise. This makes them perfect for jobs that require a lot of takes and landings such as in orchards and city areas. Between hybrid and fuel cell, the latter is better for more demanding jobs such as long range missions as it offers more energy for continuous work in open fields. With the fixed-wing VTOL, there’s the benefit of being able to take and land vertically WHILE also having a long flight duration. This is a perfect set up for big area remote surveys. They highly improve the efficiency of coverage and the continuity of the job.

Flight stability also has a big effect on the safety and precision of the operation so it is important. In order to improve the stability, safety and precision, modern drones come with the ability for automated flight planning and RTK ground positioning. This means that the drone is able to better repeat tracks in the air and complete tasks more efficiently. Wind resistance also depends on the type of terrain and orchards being flown over. To further improve safety, modern drones also have multiple motors and control channels. This allows the drone to continue operating in case one of the systems has a malfunction.

Compatibility and Extended Functionality

Having the right sensors and software to work together is essential in precision ag operations. Most modern agricultural drones come with the capability to use multi-spectral or thermal cameras to monitor areas such as crop health, pest and disease scouting, and soil assessments. Combined with GIS or NDVI mapping, data analyses can be taken even further, as reliable insights can be obtained for variable rate applications and precision agriculture management. Also, ground control stations or mission planning software add to the further automation of operations (i.e. drones can be batch scheduled and tasks be performed in an optimized and automated manner).

When choosing a drone, one should make sure the platform of the drone is compatible with the software ecosystem required for the tasks at hand, including sensor driver and data management support. Also, one should assess if the drone offers third party add-on flexibility for modules such as LiDAR or spreading systems, as this improves the drone’s overall versatility and is an indicator of the drone being able to adapt to future changes and needs within the agriculture industry.

Different Agricultural Drones Model Categories and Applicability

Agricultural drones can be classified into several categories according to their design, each suitable for different operating scenarios:

| Drone Type | Advantages | Limitations | Typical Use Cases | Example Models / Notes |

| Multirotor | – Vertical takeoff and landing (no runway required) – Simple flight control, suitable for precise spraying and monitoring – Ideal for orchards, small plots, and complex terrain | – Limited endurance (15–30 min) | Small-area spraying, high-precision monitoring, orchard or greenhouse operations | — |

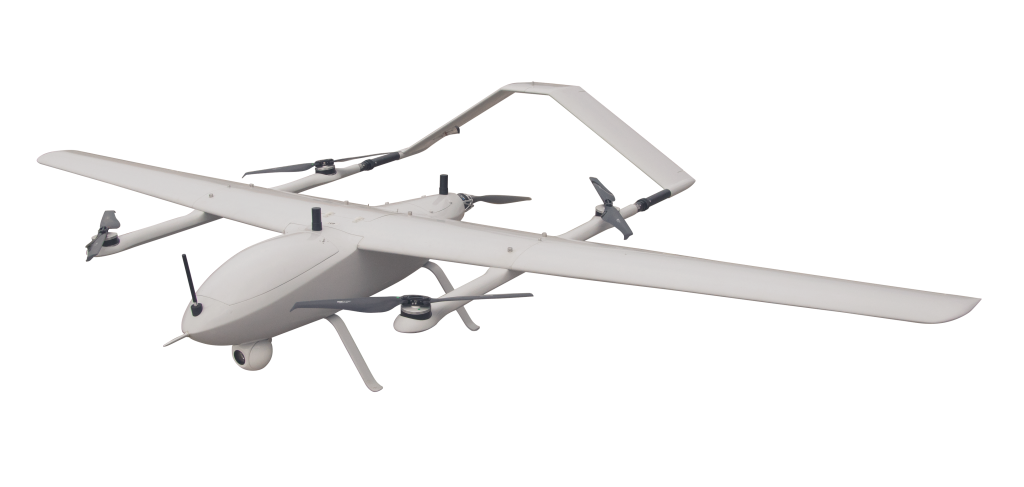

| Fixed-Wing / VTOL Hybrid | – Combines vertical takeoff and landing with long-endurance cruising efficiency – Efficient for covering large areas | – Requires slightly more space for takeoff/landing compared to small multirotors | Large-area mapping, regional monitoring, long-distance surveys | VastArrive Electric VTOL Fixed-Wing: balances endurance and maneuverability |

| Heavy-Lift Platform | – High payload capacity for spraying or material transport – Significantly improves per-hour operational efficiency | – Larger size may limit operation in very small or obstructed areas | Large-scale spraying, heavy material transport, intensive operations | VastArrive VA-W280: heavy-lift capability and long endurance make it competitive for large-scale agricultural tasks |

Safety, Regulations and After-sales Service

Safety and Flight Stability

Drones used in agriculture have to have the right safety and stability features to operate effectively in all types of conditions and situations. Waterproof and dustproof designs, fail-safe combustion engines, automatic Return to Home features, low battery Return to Home, as well as obstacle and terrain following capabilities, are all very important functionalities to have as these will improve overall reliability and safety and reduce the chances of losing equipment. These considerations are very important for professional use of drones in agriculture.

Regulatory Compliance and Pilot Certification

The use of agricultural drones is regulated the same way as aviation and agriculture. Regulations differ for each region, so some of the general rules may not apply. General industry concerns regulate drone Remote ID registration and legal recognition, drone pilot licensure, or certification for large commercial/high altitude systems, and adherence to operational constraints, including altitude restrictions, no-fly zones, and specific crops to be sprayed. Knowing and following the rules is important for legal and operational agricultural seamless ag operations.

After-Sales Support

Having good customer service is important when it comes to using agricultural drones during busy times. Key is quick service to fix problems. You should also have a way to easily replace important parts like batteries and motors, and have training along with maintenance and troubleshooting guides. Picking a drone brand that has good customer service allows you to keep working, spend less time waiting, and protects your investment.

Conclusion

You have to align your operational needs with a drone’s physical attributes to choose the right agricultural drone. Different drone types work better with specific farm work: Multirotors will work best in complex smaller farms, in contrast, VTOL/Fixed-wings is better in larger farms, and heavy-lift ones are better in more agriculture-labor intensive large-scale farms.

The other important attributes that go with the agricultural drone is the safety features, and regulatory compliance. Features that support the safety of the farmer, the drone, and the farm’s compliance to local regulations help the drone work with the farms uninterrupted and allow the farmer to work more and not have to worry.

Related Products