Power Line Inspection Drones

Unmanned aerial vehicle power line inspection is becoming a new type of productivity in the low-altitude economy. With its core values of improving efficiency, safe operation, adaptability to extreme environments, and emergency response, it is replacing manual inspection, solving problems in complex terrain and dangerous areas, and ensuring safety and stability.

VastArrive UAV: Aerial Perception & Intelligent Processing

Modern power line inspection drones covering multiple scenarios such as ultra-high voltage lines, new energy power plants, and urban power distribution networks, gradually extending to complex tasks such as nighttime emergency lighting and disaster emergency delivery.

Power Channel Environmental Monitoring

Equipped with sensors, it can quickly scan the power line corridor, monitor external threats such as tree obstructions and landslides, and inspect equipment defects such as tower structure and insulator damage at close range.

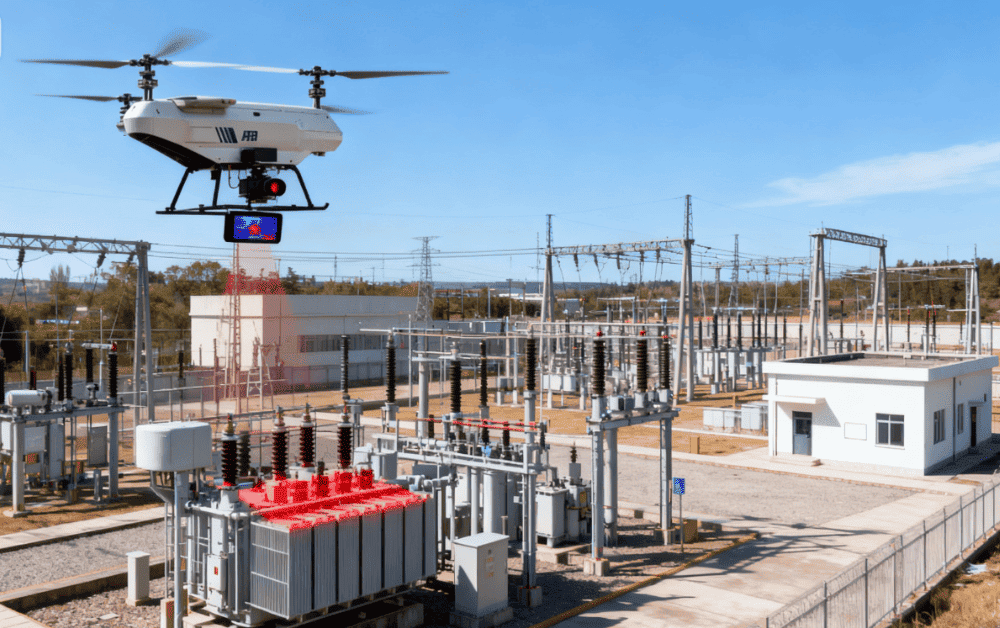

Power Station Equipment Inspection

Timely identification of defects such as hot spots and microcracks in components; visual inspection and infrared thermography of high-altitude equipment; assessment of risks such as wildfires and construction within the passageway.

Power Grid Base Station Construction

High-precision scanning of power transmission lines, combined with radar assessment of external risks, establishment of temporary base stations, and restoration of communication networks.

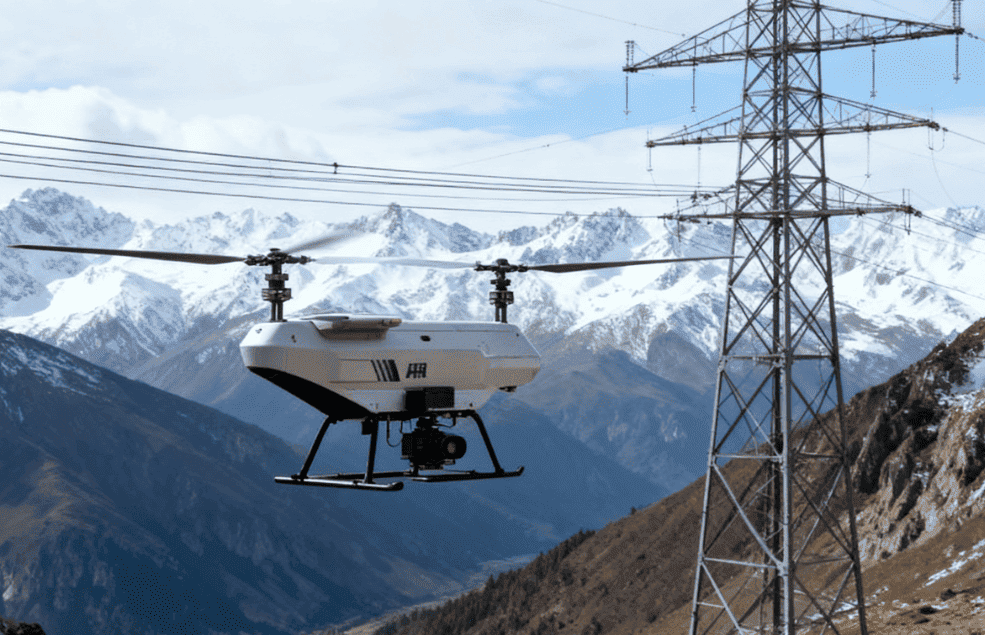

Inspection of Remote & Complex Terrain

Equipped with high-definition cameras, infrared thermal imagers, lidar, and other equipment, it conducts comprehensive monitoring of power facilities and enables data analysis and evaluation.

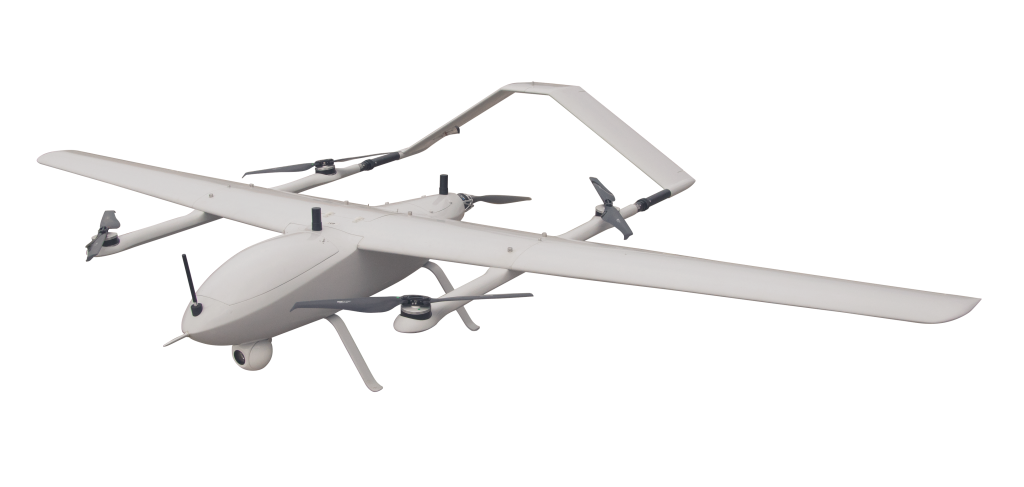

VastArrive Drones for Power Line Inspection

Explore our drones equipped with advanced sensors and autonomous flight technology for safe, precise inspections.

Start Using Advanced Drones for Reliable Power Line Monitoring

Key Features of VastArrive Drones for Power Line

Improving Inspection Efficiency

Drones can quickly cover large areas, and their autonomous navigation capabilities enable them to complete long-distance route inspections in a short time. Compared to traditional methods, efficiency can be increased by 3-10 times.

Ensuring Personnel Safety

Traditional inspections require personnel to climb poles or traverse complex terrain, facing risks such as electric shock and falls from heights. Drones, on the other hand, are remotely operated, avoiding personnel contact with high-voltage equipment or entry into dangerous environments, with significant advantages, especially in mountainous areas and during severe weather.

Precise Defect Location

Equipped with high-definition zoom cameras, infrared thermal imagers, and other equipment, drones can detect millimeter-level wire cracks and insulator damage, and monitor abnormal equipment temperatures in real time. Through thermal imaging technology, they can also detect potential overheating hazards at line joints, enabling early fault warnings.

Adaptable to Complex and Remote Terrain

Drones can easily handle complex terrains such as mountains, canyons, and urban building complexes, filling blind spots for manual inspections and solving problems that are difficult to reach using traditional methods.

Reduced Costs

Less reliance on manpower and high-altitude equipment results in long-term maintenance costs that are only one-third of traditional methods. Data is automatically generated into digital archives, saving time on subsequent data processing.

True Stories: VastArrive Power Line Drones in Action

See how VastArrive power line drones help detect issues early, enhance safety, and prevent outages.

Unlock More Applications Beyond Power Lines of VastArrive

VastArrive drones cover multiple industries, meeting diverse needs and unlocking new possibilities.

FAQs about Power Line Inspection Drones

Contact for More Information

Focus on quickly responding to your needs and customizing exclusive services from a professional perspective